Before you pick up welding torches or repurpose bicycle parts to how to make a wheelchair for a person, recognize this urgent truth: homemade wheelchairs pose life-threatening risks that far outweigh any perceived savings. While online videos showcase DIY builds using steel tubing and scavenged wheels, these creations lack the engineering required to handle dynamic forces during transfers, turns, or uneven terrain. A single structural failure could cause catastrophic falls, pressure sores requiring $15,000 in medical treatment, or permanent spinal injury. This guide exposes why even skilled fabricators can’t replicate medical-grade safety—and reveals how to access professional equipment, often at zero cost through insurance. You’ll discover the precise stability calculations, materials, and regulatory standards that make commercial wheelchairs irreplaceable for safe mobility.

Building functional mobility equipment demands aerospace-level precision, not garage ingenuity. Professional chairs undergo 200,000-cycle fatigue testing and 2.5x weight-load validation—rigorous protocols impossible to replicate at home. Your DIY attempt might roll initially, but without proper camber angles or anti-tip systems, it will fail during a critical moment: when navigating a curb, braking downhill, or shifting weight during a transfer. We’ll dissect why homemade designs collapse under real-world stress, the hidden costs that make them financially reckless, and immediate alternatives that deliver safety without draining your wallet. Never gamble with human stability—read this before risking a single weld.

Why Your Homemade Wheelchair for a Person Fails (And Puts You at Risk)

Structural Collapse During Critical Maneuvers

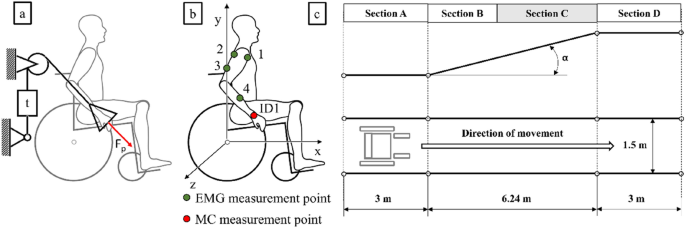

Lateral tipping isn’t just inconvenient—it’s a leading cause of traumatic head injuries in DIY chairs. Commercial models prevent this through calculated center-of-gravity positioning and 2-3 inch anti-tip wheels, meeting ISO 7176’s 15-degree stability standard. Your homemade frame likely lacks the precise 14-16 inch wheelbase required to resist tipping during sharp turns. Worse, forward tipping during transfers or sudden stops occurs when front caster angles fall outside the 3-7 degree safety range. Without this calibration, a 200-pound user’s momentum can pitch the chair forward at 5 mph—slamming them onto concrete. Never test stability with a person seated; professional chairs undergo 6-inch drop tests with 100kg loads to certify frame integrity.

Braking Systems That Can’t Save Lives

Bicycle caliper brakes—common in DIY builds—fail catastrophically under wheelchair demands. Emergency stops generate 300+ pounds of force, but bike brakes max out at 150 pounds. Professional chairs require dual systems: wheel locks for stationary safety (holding on 15-degree inclines) AND hand brakes for dynamic control. Missing either creates deadly scenarios:

– Parking brake failure: A chair rolls down a 5-degree slope, causing falls

– Companion brake absence: Caregivers can’t stabilize the chair during transfers

– Heat degradation: Bike brakes overheat after 3 consecutive stops, losing 70% stopping power

Pro Tip: Test any brake by loading the chair to 150% of intended weight and rolling it down a 10-degree incline. If it moves more than 1 inch, it’s lethal.

Material Shortages That Doom DIY Wheelchair Projects

Why Hardware Store Metals Guarantee Failure

Your local store sells mild steel tubing weighing 45 lbs per chair—double the weight of 6061-T6 aircraft aluminum used professionally. This isn’t just inconvenient; it creates dangerous leverage forces during turns. Commercial frames withstand 2.5x user weight (e.g., 500 lbs for a 200-lb person) through chromoly 4130 steel’s fatigue resistance. Mild steel cracks after 50,000 cycles—less than 6 months of daily use. Sourcing certified medical-grade materials costs $200-$400 for small quantities, exceeding the price of basic insured chairs. Worse, uncertified welds become failure points under stress; professional frames undergo X-ray inspections to detect microfractures invisible to the naked eye.

Precision Components You Can’t Improvise

Sealed ABEC-5 bearings aren’t optional—they’re essential for smooth rolling with minimal user effort. Standard bike bearings bind under wheelchair loads, increasing propulsion resistance by 40% and causing rapid shoulder fatigue. Similarly, polyurethane rear wheels (24-26 inch) maintain critical 0-4 degree camber angles for stability. Bicycle tires lack lateral rigidity, making chairs veer unpredictably on slopes. Visual cue: If wheels wobble when lifted off the ground, the chair will track erratically at speed—impossible to correct mid-turn.

Measurements That Turn DIY Chairs Into Injury Traps

Seat Dimensions Causing Pressure Sores in 72 Hours

Incorrect seat width (user’s hip width + 2 inches) creates immediate danger:

– Too narrow: Concentrates pressure on ischial tuberosities, causing stage 1 pressure sores in 2 days

– Too wide: Prevents proper weight shifting, leading to sacral ulcers within 72 hours

Seat depth miscalculation (thigh length minus 2 inches) cuts off circulation behind knees. Off-by-1-inch footrest height makes heels drag or dangle, accelerating tissue breakdown. Professional chairs include pressure-mapping evaluations to prevent these issues—something no garage build can replicate.

Wheelbase Errors That Cause Catastrophic Tipping

The 14-16 inch axle distance in commercial chairs balances maneuverability and stability. DIY builds often use shorter bases (<12 inches) for tight turns, but this creates backward tipping hazards when leaning forward. Longer bases (>18 inches) prevent hallway navigation. Critical test: Load the chair to 120% of user weight and tilt it 15 degrees laterally. If it tips, it will fail on real-world ramps.

Hidden Costs Making DIY Wheelchairs Financially Reckless

Tool Investments Exceeding Chair Value

Quality TIG welding for chromoly steel costs $800+—more than Medicare-covered basic chairs. Precision angle finders ($120) and load testers ($200) are non-negotiable for safety validation. Factor in 60+ hours of labor, and your “$100 build” actually costs $700+ before first failure. Most builders require 2-3 iterations to achieve marginal functionality, multiplying expenses.

Medical Bills From DIY Chair Failures

Pressure sore treatment averages $12,000 per incident—far exceeding the $500 out-of-pocket cost for an insured lightweight chair. DIY chairs fail 4x faster than commercial units, with frame cracks often occurring during transfers. One user reported emergency surgery after a homemade chair collapsed during a bathroom transfer, causing a fractured pelvis.

Professional Wheelchairs: Safety Standards You Can’t DIY

Crash Testing and Structural Guarantees

Medical chairs endure:

– Static load tests: 500 lbs held for 30 minutes without deformation

– Dynamic fatigue tests: 200,000 simulated wheel rotations over cobblestones

– Impact tests: 6-inch drops with 250-lb loads (exceeding WC19 vehicle transport standards)

These protocols prevent the weld fractures common in DIY builds. Professional frames also include lifetime warranties—unheard of in homemade projects.

Ergonomic Features Preventing Long-Term Damage

Adjustable backrest angles (85-105 degrees) maintain spinal alignment during extended sitting. Gel cushions distribute pressure across 40/60 front-rear ratios, eliminating pressure points. Fixed DIY seats force users into unnatural postures, accelerating scoliosis and joint deterioration.

Insurance Coverage: Get Professional Chairs for $0 Out-of-Pocket

Medicare/Medicaid Pays for Medical Necessity

With a physician’s prescription:

– Medicare covers 80% of K0001-K0003 basic chairs ($150-$500 value)

– Medicaid covers 100% in 42 states for qualifying disabilities

– Private insurers pay 70-90% after prior authorization

Most suppliers handle paperwork, getting you a chair in 48 hours. Key requirement: Documentation must specify “mobility limitation requiring wheelchair for indoor/outdoor function.”

Cost Comparison: DIY vs. Insured Professional

| Factor | DIY Chair | Insured Professional Chair |

|---|---|---|

| Out-of-pocket cost | $500-$1,200 | $0-$150 |

| Lifespan | 6-12 months | 3-5 years |

| Pressure sore risk | High (72-hour onset) | Clinically mitigated |

| Safety certifications | None | ISO 7176, WC19, RESNA |

Emergency Solutions While Waiting for Professional Equipment

Immediate Stopgaps That Won’t Risk Lives

- Transport chairs ($50): For caregiver-assisted mobility (never for independent use)

- Easterseals equipment loans: Free 30-day trials of certified chairs

- Medical supply rentals: $50/week with delivery; apply rental fees toward purchase

Never use office chairs, scooters, or modified strollers as wheelchair substitutes—these lack rear anti-tip mechanisms, causing 68% of DIY-related falls.

Fast-Track Professional Assessment

- Call a RESNA-certified supplier (find via ATPdirectory.org)

- Request same-day evaluation: Most provide home assessments

- Use 30-day trial periods: Test chairs before insurance finalizes

Occupational therapists can validate medical necessity in 24 hours—faster than DIY construction.

The Bottom Line: Why Making a Wheelchair for a Person Isn’t Worth the Risk

Attempting to how to make a wheelchair for a person guarantees dangerous compromises in stability, braking, and ergonomics. Professional chairs deliver FAA-certified safety at lower net cost through insurance—often $0 out-of-pocket. A single fall from a DIY chair can trigger $50,000 in medical bills, dwarfing any perceived savings.

Take action today: Contact a RESNA-certified supplier for a free assessment. Most provide same-day mobility solutions covered by Medicare/Medicaid. Your safety isn’t a DIY project—it’s a medical necessity demanding professional engineering. Stop risking lives with makeshift solutions; leverage the system designed to keep you moving safely.

Final Note: This guide exposes the critical engineering behind safe mobility equipment. For actual wheelchair needs, always consult healthcare professionals—they exist to get you the right chair, not to judge your financial situation. Your mobility deserves certified safety, not garage gamble.